About Us - Innovation - Overview - www.ussteel.com

INNOVATION

CUSTOMER CENTERED.

FUTURE FOCUSED.

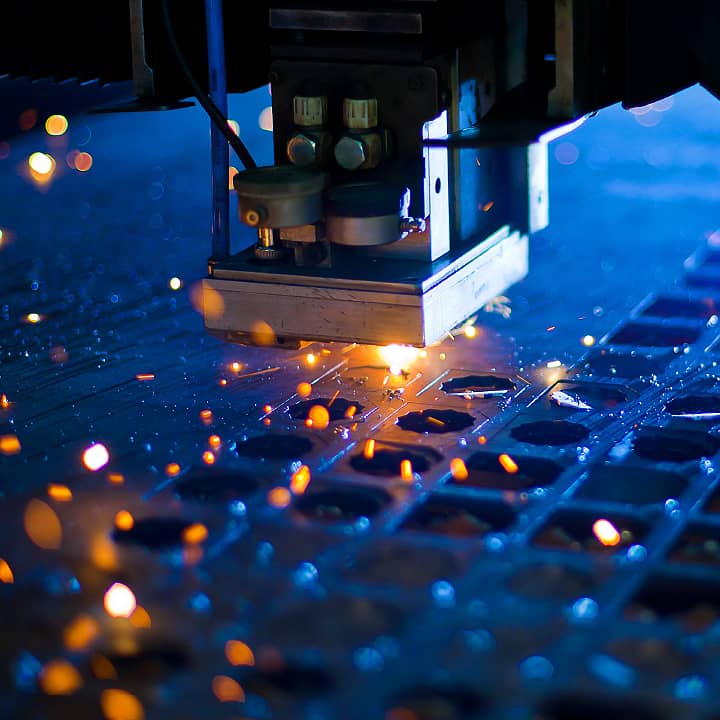

U. S. Steel’s Research and Technology Center is where industry-leading expertise and state-of-art laboratory facilities join with customers to advance the science of steel. Here, we discover, test and process-engineer the world’s next generation of steel products and applications.

U. S. Steel customers have long recognized our company as an industry leader and valued partner in the production of high-value-added steel sheet and tubular products. Our solutions are highly sought after by manufacturers in the automotive, appliance, construction, container, and oil and gas industries. Our research organization has been a key factor in both customer and U. S. Steel success—research and technology excellence in steel products and processes is the foundation of a bright future for us, our customers and the world.

The men and women of U. S. Steel’s research organization are passionate about developing new steels and manufacturing processes for tomorrow’s applications. We provide world-class support to the company’s operations around the world, and collaborate with customers to meet evolving market needs with cutting-edge solutions.

RESEARCH AND TECHNOLOGY CENTER

U. S. Steel’s sophisticated steelmaking processes and market-leading products reflect more than a century of research and innovation. At our world-class Research and Technology Center in Munhall, PA, academic scientists, leading steel industry experts and our customers come together, applying advanced technology to drive premier product development and production.

The Research and Technology Center does its work in two focus areas:

PROCESS TECHNOLOGY PRODUCT TECHNOLOGY

AUTOMOTIVE RESEARCH & TECHNOLOGY

Since our beginnings, we have applied leading steelmaking innovation to support automotive customers looking to drive next-generation advances in safety, fuel efficiency, vehicle production costs and style. Our Product Technology Group’s Advanced Applications Technology staff conducts customer application research, test services and development projects—often carried out jointly with our customers—to support automaker innovation and competitiveness.

Learn MoreBIG RIVER STEEL: A HISTORY OF FIRSTS

The world’s first Flex Mill®, designed from the ground up to optimize the flexibility, agility and capabilities of mini mill steel technology. One of the world’s first LEED-certified steel mills, reflecting a leader’s commitment to sustainable steelmaking. The first steel mill in North America to combine an electric arc furnace with a Ruhrstahl Heraeus (RH) degasser for cleaner, more formable steels. Big River Steel's history of firsts brings mini mill excellence to U. S. Steel, along with an innovator’s question-everything mentality that fits perfectly with our Best for All® strategy and vision.

Combining Big River's mini mill leadership with U. S. Steel's industry-best steel finishing expands the horizon for a new round of firsts, starting with verdeX® sustainable steels.

Learn MoreU. S. STEEL TUBULAR PRODUCTS

RESEARCH & DEVELOPMENT

U. S. Steel is a leader in tubular products serving the Oil & Gas (O&G) and other industries for a reason. From the U. S. Steel Buttress Thread, which has been the API standard for O&G since 1961, to the newest-generation USS-LIBERTY TC® premium connection, our Research and Technology teams have been a valuable innovation partner to our tubular customers. We are always working to develop new products and solutions to move our customers—and the industry—forwardLearn More

USSE RESEARCH – KOŠICE, SLOVAKIA